Civil/Utilities

Fiberglass Geogrid High-Strength Reinforcement for Paving and Soil Stabilization

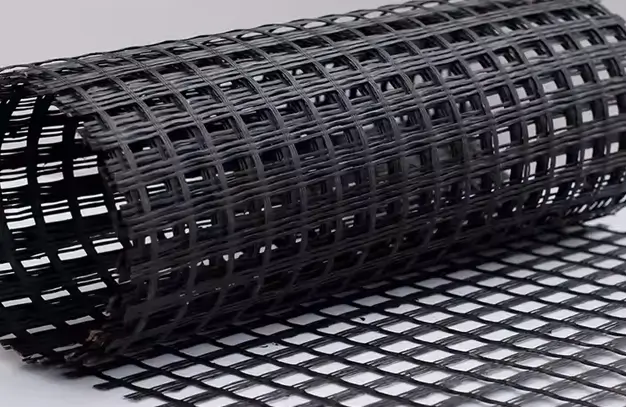

Fiberglass Geogrid is a high-performance geosynthetic material designed to enhance the strength and stability of infrastructure projects. Manufactured from high-strength glass fibers with a specially designed polymer coating, it delivers superior tensile strength, durability, and ease of installation. Its pressure-sensitive adhesive backing ensures a quick and efficient bond with surfaces, making it an ideal solution for road construction and rehabilitation projects.

Key Benefits of Fiberglass Geogrid

- Cost-Effective Solution: Reduces maintenance costs by prolonging the life of pavement structures.

- Environmental Sustainability: Minimizes material waste and supports eco-friendly construction practices.

- Ease of Installation: The adhesive backing and lightweight design streamline application processes.

- Long-Term Performance: Resistant to harsh environmental conditions, ensuring durability and consistent performance over time.

Applications of Fiberglass Geogrid

- Paving Projects: Enhances the structural integrity of asphalt and concrete pavements, reducing cracking and extending lifespan.

- Soil Stabilization: Reinforces subgrades and prevents deformation under heavy loads.

- Infrastructure Support: Used in roadways, parking lots, airports, and other civil engineering projects requiring robust ground reinforcement.

- Erosion Control: Prevents surface erosion by stabilizing the soil and distributing loads effectively.

Key Features of Fiberglass Geogrid

- High Tensile Strength: Provides excellent reinforcement, improving load distribution and preventing pavement cracking.

- Pressure-Sensitive Adhesive Backing: Simplifies installation, ensuring an efficient bond with asphalt or concrete surfaces.

- Durability: Resists environmental stress, ensuring long-term performance in various construction conditions.

- Flexible Design: Easily adapts to both asphalt and concrete surfaces, providing versatile application options.

With its innovative design and reliable performance, Fiberglass Geogrid offers unmatched support for infrastructure development, paving projects, and soil stabilization.

FAQ questions for Fiberglass Geogrid

The purpose of geogrid is to provide reinforcement, improve load distribution, and stabilize soil in construction projects. It helps prevent deformation in roads, pavements, and foundations, enhancing the structural integrity and longevity of infrastructure.

Geogrid fabric is used for reinforcing soils, stabilizing subgrades, and supporting pavements. It is commonly applied in road construction, retaining walls, embankments, and erosion control projects.

Geogrids are classified into three main types:

- Uniaxial Geogrids: For reinforcement in one direction, ideal for retaining walls.

- Biaxial Geogrids: Provide reinforcement in two directions, used in road and pavement construction.

- Triaxial Geogrids: Offer multi-directional strength, suitable for advanced soil stabilization applications.

Geogrids are used in road construction, pavements, retaining walls, embankments, parking lots, airports, and other infrastructure projects requiring soil stabilization and load distribution.

Use geogrid when constructing roads, pavements, or retaining walls where soil needs reinforcement and load distribution to prevent deformation and cracking. It is also essential in areas prone to erosion or heavy traffic loads.

Some disadvantages of geogrids include:

- Potential higher initial cost compared to traditional methods.

- Requires proper installation techniques for optimal performance.

- Not suitable for all soil types without proper engineering design.

Geogrids have a long lifespan, often exceeding 50 years, depending on the material, environmental conditions, and proper installation.

Advantages:

- Reinforces soil and prevents deformation.

- Extends the lifespan of pavements and structures.

- Reduces material and maintenance costs.

Disadvantages:

- May require specialized installation expertise.

- Not universally applicable to all soil conditions without design adjustments.

Geogrids are installed by laying them on prepared subgrades, anchoring the edges, and layering soil or aggregate over them. Proper tensioning ensures maximum effectiveness in reinforcement and load distribution.

Use geogrids for soil reinforcement and load distribution, while geotextiles are better for filtration, separation, and drainage applications. In projects requiring both, they can be used together as a composite solution.

Geogrid enhances pavement performance by reinforcing the base layer, preventing rutting, and reducing cracking. It increases the pavement’s lifespan and reduces maintenance costs.

The price of Fiberglass Geogrid varies based on specifications, size, and project requirements. It is recommended to contact our team to get accurate pricing information.